History

After three years of crippling seasonal frosts at Broadacres Blackcurrant farm in Canterbury, Bruce Koller and Nigel Green came up with the concept, and involved Fred Phillips in the design and evaluation phase. Bruce funded the investment and Nigel, with support from father Bruce Green, physically built the first two prototypes and ran them for three years.

These efforts have proven the effectiveness of directional warm air over the crop, preventing frost damage on up to 8 hectares of blackcurrants over several seasons. This world leading break-through worked, but the way in which it worked and the limits of the method were not fully understood. The aim was is to improve on this with a new prototype machine by developing a model to predict the aerodynamics behind the way it worked and to improve the design and functionality with a much more efficient fan, and heater to compliment the sophisticated aerodynamics. The target being to provide warm air, cost effectively, over at least 10 to 15 hectares.

The Evolution

The following pictures show the evolution and development over the last 4 years from the initial concept machine that has been working all that time to the new generation machine being assembled on the factory floor right now.

This machine, has successfully protected the blackcurrants over several seasons

The pots were used to provide heat

The template for the burner.

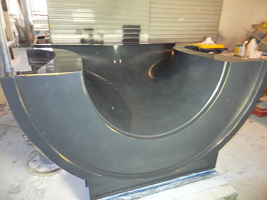

The fibre glass mould.

Some of the parts out of the mould.

Ullrich Aluminium has done the leg extrusions.

The mounting base for one of the legs that has been machined and tapped for precise positioning.

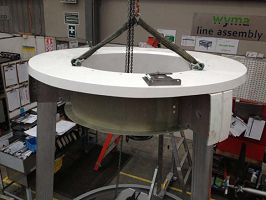

Heat-ranger being constructed.

Fixed 17.5 metre masts that have temperature recorders at 2.5 m intervals as well as 5m mobile masts so that we can measure the machine’s performance.